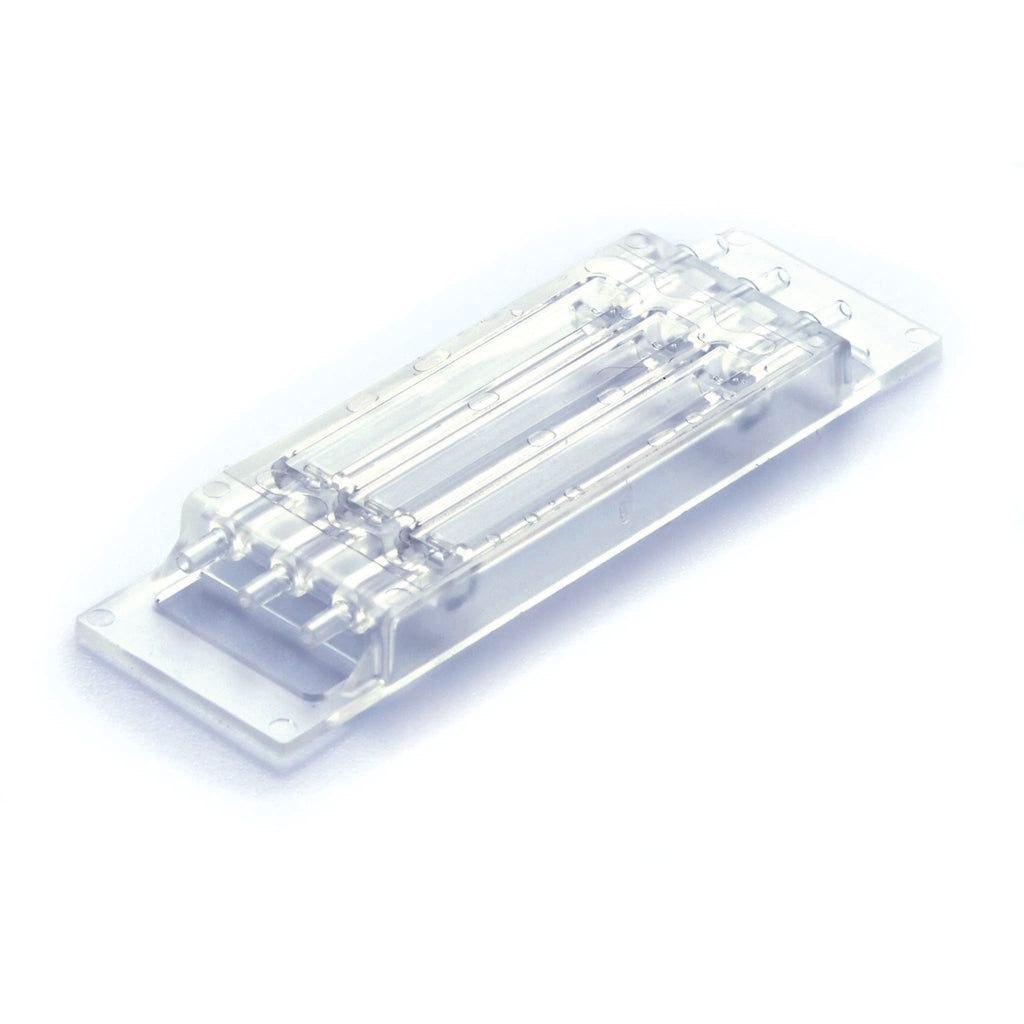

IBI 3-Channel Flow Cell - Sterile with #1 Glass Cover Slip

The IBI 3-Channel Flow Cell, formerly the Stovall 3-Channel Flow Cell, is a sterile, single-use solution for affordable and efficient biofilm creation. This device features three separate channels, enabling the simultaneous growth of three distinct biofilms within a single flow cell. Equipped with a #1 Glass cover slip, the underside serves as the attachment site for biofilm growth, allowing real-time, non-destructive analysis using traditional light or confocal laser microscopy for 3D imaging.

Each cell is gamma irradiated for sterility, sealed, and ready to use with existing reusable flow cell systems. After the experiment, the cover slip can be removed with a handheld glass cutter for further analysis. This flow cell is ideal for precise biofilm research, offering reliability and convenience. Proudly made in the USA and designed for high performance.

- Specifications

- Operation Manual

- Technical Information

- Peristaltic Pumps

- Parts and Accessories

3-Channel Flow cell ONLY includes:

One, 3-channel cell w/#1 Glass Cover Slip. Gamma Irradiated in sealed packaging. Typical flow rates thru 3-channel cell: 3ml – 5ml per/hour for each channel. Sold for use in an existing flow cell system. For one-time use only.

3-Channel Manual:

FAQs and Answers:

In the flow cell there are two different surfaces, top surface which is made of glass slides, and the bottom surface which is made of plastic. So my question is the bottom surface also as smooth as the top surface, or is it rough to enhance the attachment of the bacteria? If I grow the biofilms on the top surface instead of bottom surface by flipping the system, will the biofilms will be same or not??

Most Biofilms are grown on the top surface (or underside of the glass slide). This allows for slightly better observation of the biofilm via microscope. The bottom surface will also grow most Biofilms but it is slightly more abrasive than the top surface. To grow on top surface, the bacteria is introduced while the cell is turned upside down (glass surface facing downward) and allowed to sit still with no media flowing for maybe an hour or more to allow attachment and growth to begin.

Can flow cells be heated?

Yes, flow cells can be heated. For most biofilms to grow, the recommended temperature is from mid 30° to 42° C. What limits the temperature range for experiments are the different strengths and expansion coefficients between glass and plastic and the fact that at elevated (i.e. higher than 42°) temperatures the glass and plastic begin to upset the bonding glue which holds them together.

What is a recommended Flow Rate for the culture media through a flow cell?

There really isn’t a “recommended” flow rate. Different Biofilm cultures can require different flow rates of culture media. A “Suggested” flow rate or starting point is around 5ml per/hr. To calculate this flow rate there are several things that must be taken into consideration, such as: Tubing I.D. the specifications of the pump being used (the number of pump rollers affects the flow rate, see pump manual) and the number of channels in the flow cell (3-channel VS convertible). For a 3-channel cell: Dis-connect effluent tubing from waste bottle and allow to flow into a 100 ml graduated cylinder. Allow to flow for exactly 10 minutes. After 10 minutes measure the amount of liquid in the graduated cylinder. Example: If 10 ml of liquid is measured in the graduated cylinder after 10 minutes, you have a 1 ml per/min flow. Since this is a 3-channel cell, you divide that by 3 which equates to .33 ml per/min through each cell. Adjust the pump accordingly to reach your desired flow rate.

What is the I.D. (Inner dimension) of the inlet and outlet tubing on the 3-channel flow cell?

There are 2 different types of tubing on the 3-channel flow cell full assembly.

From the lead manifold to the inlet of the bubble trap is peristaltic pump tubing. Tygon E-LFL - measures 1.1mm Inner Diameter.

From the output of the bubble trap to the 3-channel cell and beyond is PVC tubing Dimensions: 1/8" O.D. x 1/16" I.D.

What is the overall length of the Flow cell assembly?

The overall length of the complete flow cell assembly is 91”.

What type of glue is used on the tube fittings found on the culture media bottle caps?

The glue used is a 3M product. It is a 2-part Epoxy that is rated for 162° C which should allow for autoclaving of the entire bottle and cap without issues.